At present, parameters of the internal structure of China’s sealed deep groove ball bearings are just about the exact same as that of foreign products. Even so, the level of vibration and noise of such merchandise is really diverse from that of foreign products. It is mainly resulted from the manufacturing things and operating situations. From the point of view of the bearing business, the operating situation factors can be thought of via producing reasonable demands on the primary engine. Even so, how to lower vibration and noise that are triggered by the manufacturing is grow to be an urgent problem for the bearing industry.

Lots of tests from dwelling and abroad show that: the processing high quality of the cage, bearing ring, and steel balls has different effect on the bearing vibration. Among all of them, the processing high-quality of steel balls has the most considerable impact on the bearing vibration. The key things that have influences are roundness of bearing rings, the waviness, surface roughness and surface bump and hurt.

The most prominent challenge of China’s steel ball merchandise is that vibration value is large. The surface has critical defects (such as single point, cluster points and pits). Even although the surface roughness, size, shape and errors are not reduced than the level of outside rings, the bearing vibration worth is pretty higher soon after the mixture. The primary challenge is that the ripple is not controlled.

As to the rings, most really serious impacts on the bearing vibration are the channel waviness and surface roughness. For instance, if the circularity of inside and outside channel of little and medium sized deep groove ball bearings is bigger than 2μm, it will have distinctive effect on the bearing vibration.

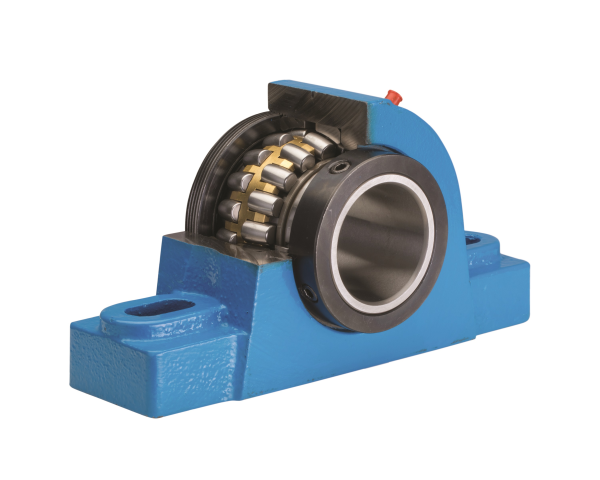

pressed steel bearing housing is resulted from grinding as to the steel balls and rings. Even though superfinishing can increase the waviness and reduce roughness, the most fundamental measure is to cut down the grinding process of waviness and prevent random bump and hurt.

How to lessen noise of ball bearings? There are two points which really should be taken into consideration. 1 is the manufacturing approach. The refinement of the manufacturing course of action primarily refers to the shortness of the approach and the combination of the approach and manufacturing. The process of the manufacturing ought to be clean. Apart from, bearings ought to be created in a massive scale for this can enhance the competitiveness in the planet industry. The other is the gear. High-speed grinding, spindle accuracy, stiffness and a lot of other detection performances have considerably effect on the grinding accuracy and efficiency.

SeekPart is the international B2B platform in the industry of mechanical parts. SeekPart aggregates the trade leads in this location, and our ultimate target is to advantage the purchasers and sellers of mechanical parts by using these leads by way of our on the net tools.